The Hybrid Relay is a combination of electro-mechanical and semiconductor technology. It uses the advantages of both while minimizing their disadvantages. The main benefits of EMR are a minimal voltage drop while the circuit is closed and no leakage currents while it is open. The main advantages of SSR or Triac are high durability and no interference generation. The Hybrid Relay has all of these.

You can find such ready relays in online shops, but they are industrial solutions and cost a fortune. However, you can create it yourself.

A lot of information here will result from articles about Triac and Electromagnetic Relay. Therefore, if something seems not clear just go back for a moment and read again 🙂

Let’s create our long-lasting non-interference Relay!

Hybrid Relay construction

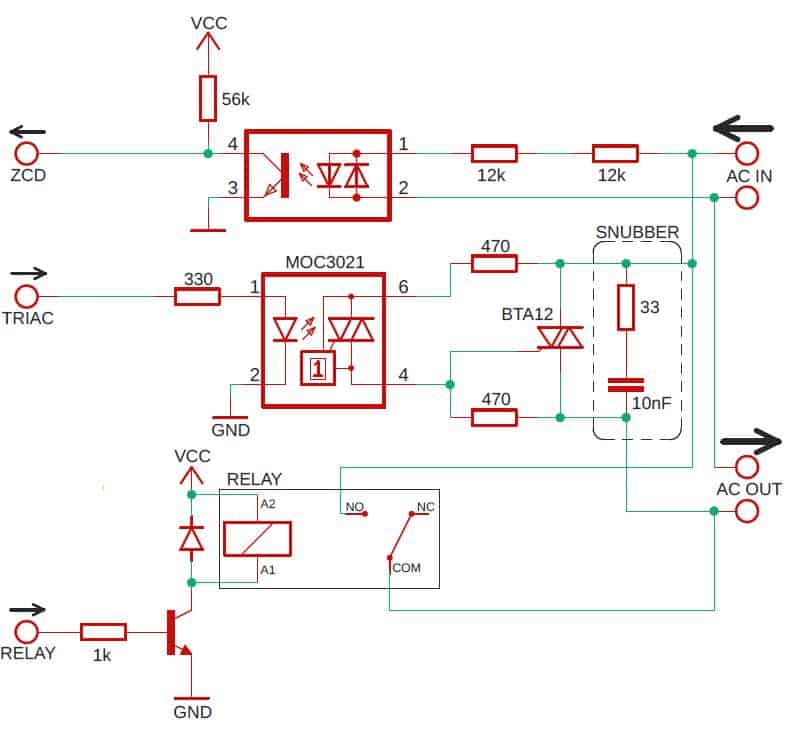

The Hybrid relay consists of two parts: electro-mechanic and semiconductor.

The first part is the classic electromagnetic relay. The second part can be SSR or Triac. We have to handle Zero Cross Detection ourselves, so there is no point in using SSR. It would take only more space unnecessarily. Let’s use Triac then.

At first glance, the schematic may seem complicated to you. However, this is nothing more than combined two schematics, which we discussed earlier.

Triac and EMR outputs are connected in parallel. And we can independently control both. It gives great possibilities.

How Hybrid Relay works?

The implementation of the hybrid relay is a little more challenging than in the case of SSR or EMR. But don’t worry, we will do it step by step.

As you can see in the schematic above, two INPUTS are controlling the Relay and the Triac, and one OUTPUT gets data from the ZCD. How to manage the Triac depending on the ZCD I wrote in the previous chapter. Here he would like to focus on the synchronization of Triac with the Electromagnetic Relay.

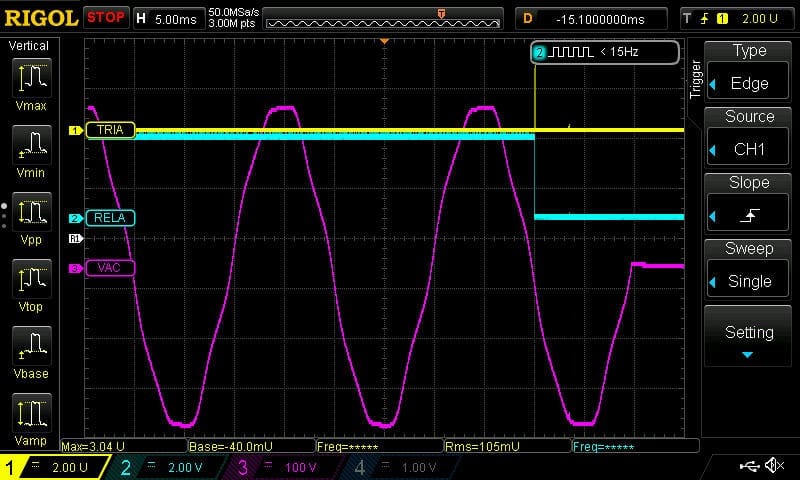

The saying “Time is an essence” fits here perfectly 🙂 To better understand this, let’s follow the process of switching ON and OFF the Hybrid Relay.

Circuit closing procedure

0 ms. – each cycle begins by detecting that AC Mains is at “zero”

The first step is to send information to Relay and Triac that they should turn on. Short impulse to Triac’s Gate and high state to Relay coil. As you know from previous chapters, Triac will close the circuit immediately. For the Relay, we have to wait a while. This Relay delay actually simplifies the procedure. So we turn the disadvantage into an advantage. At this moment, all the current flows only through Triac. But at least we started it in “zero”, so we didn’t generate noise.

~7 ms. – it is the moment when the Relay closes its contacts

Until now, all the current has flowed through Triac. And this time, we used a small, low power Triac and didn’t mount any heat sink. Fortunately, after a few ms, Relay also turns on. It has significantly lower contact resistance, so it absorbs most of the current from Triac. Thanks to it, Triac doesn’t heat up so much.

10 ms. – in the US it will be ~8 ms

At this moment, AC Mains reaches zero volts. And as we already know, this is the moment when the Triac turns off. So now, all the current flows through the relay. And Triac can relax after 10 ms of hard work.

Circuit opening procedure

The procedure for opening (switching off) the hybrid relay looks exactly the opposite to switching on.

0 ms. – each cycle begins by detecting that AC Mains is at “zero”

The first step is to send information to Relay and Triac that they should turn off. Short impulse to Triac’s Gate and low state to Relay coil. Triac will close the circuit immediately. But this time, the Relay is still on. So only a small amount of current will flow through it.

~7 ms. – it is the moment when the Relay opens its contacts

Triac takes over all the current from the load circuit. Fortunately, there is not much time left until AC Mains reaches zero volts.

10 ms. – in the US it will be ~8 ms

It is the moment AC Mains reaches zero. Triac can turn off.

Advantages

- Interference generated at switching is minimized.

- No leakage currents when the relay is open.

- Low resistance when the relay is closed.

- There is no need to use a heat sink.

- A long life time (although not as long as Triac itself).

Disadvantages

- Complicated schematic and control method.

- Phase control is not an option.

Hybrid Relay – summary

This solution is the most complex of all that I discussed in this article. This is due to quite complicated schematic and the complex control procedure. However, this rewards us with an great device for controlling large loads. You can easily connect 20 A and don’t use any heat sink. Also, you can be sure that you are not generating any crazy noises around your device.

I’m not saying that you have to use it everywhere now 🙂 Often, in simple projects, there is no point in overcomplicating the AC Mains switching system. However, it is worth being aware of this method e.g., when controlling a high power heating element.

Related Articles

How Smart Home save energy? – Real life examples

Do you want to reduce your bills by 30 –…

How to select a microcontroller?

Choosing the right microcontroller for the application is not an…

How Triac works? – The Complete Illustrated Guide

Triac is a semiconductor component that you can treat as…